JORBIN MACHINER, we promise to supply high quality machine with high competitive prices.

Expecting cooperation with you, Let us become friendly partners, common development!

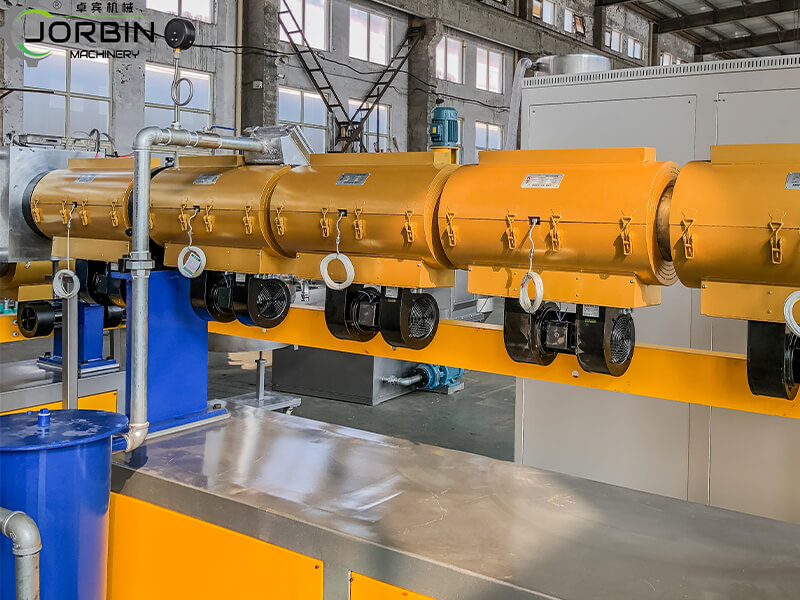

We know that the plastic extruder needs to work at a constant temperature during production, which means that we must heat the machine before starting it. Our common heating method for plastic extruders is through heating rings or heating sheets. When heat the extruder, it is necessary to install several heaters on the screw barrel of the extruder as segmented temperature control zone to ensure the heating state of each temperature control section is stable and uniform, so that the raw materials can be effectively plasticized in the screw barrel. Each temperature control zone of the plastic extruder must not only be equipped with heaters but also a cooling device to ensure the temperature stability of the extruder barrel and screw. The temperature control system of the plastic extruder plays a very important role in processing of the machine, because the its temperature directly affects the plasticization of the raw materials during the production process of plastic products. If the temperature control system of the plastic extruder is unable to work, the complete machine will not be able to perform, or even cause excessive screw extrusion pressure and damage the machine.Therefore, when selecting a heater, the optimal heater must be selected based on the materials to be produced. At present, the most commonly used heaters are cast aluminum, ceramic heaters and infrared heaters. Now let’s have a discussion on each application of different heaters.

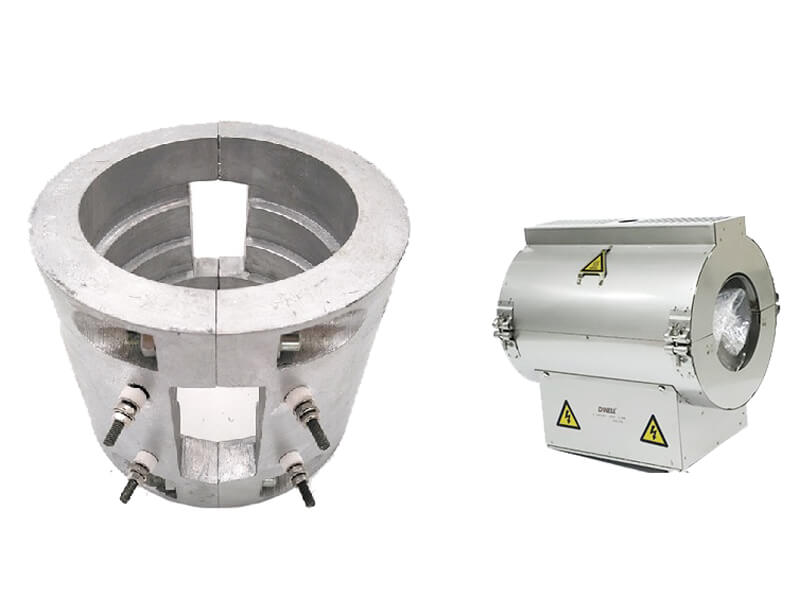

It effectively utilizes electric heating rods by bending them into required shapes and casting them into aluminum alloy to form a cast aluminum heater. In addition to the advantages of general resistance heaters, the cast aluminum heater can be made into a shape that closely matches the barrel. The electric heating rod is tightly fixed in the cast aluminum shell, making the air gap very small, which is conducive to heat conduction. At the same time, the heating wire's anti-vibration, anti-vaporization, moisture-proof, and explosion-proof properties are enhanced. Where cooling is required, a cooling coil can be cast into the cast aluminum heater. And it has low cost and long life. Therefore, this type of heater is widely used. However,its disadvantage is that it heats up slowly and is not resistant to high temperatures. The maximum temperature is around 270 degrees Celsius. Not suitable for raw materials requiring high temperature heating.

Application machine: https://www.jorbinmachinery.com/product/complete-plastic-recycling-plant-double-stage-granulator-machine.html.

Heaters that use ceramic blocks instead of mica as insulators, it has the advantages of fast heating speed, long life, easy replacement and adjustment of heater capacity, so it is increasingly used in plastic extruder machine.However, its disadvantage is that the machine cools down and dissipates heat slowly.

Application machine: https://www.jorbinmachinery.com/product/two-stage-plastic-extruder-for-pp-pe-agglomerator-granules-making-machine-with-hot-die-head.html.

Infrared heaters also have the advantages of fast heating, good heat preservation, and energy saving, and can directly replace cast aluminum heaters, ceramic heaters, etc. The temperature is controlled within ±1°C and the surface temperature is lower than 70°C, effectively improving the workshop environment temperature, improve production efficiency and product quality. While, infrared heaters also have disadvantages. The biggest problem is that the quartz tube components are easily damaged and can easily cause rupture during transportation and installation.However, with the development of technology and corporate research, the embedded structure is creatively used to protect the quartz tube and reduce its damage, and the life of the heater can be extended to more than 8-10 years.

Application machine: https://www.jorbinmachinery.com/product/complete-plastic-recycling-plant-double-stage-granulator-machine.html.

In the future journey, with the progress of the times and the development of science and technology, our company's technicians will continue to explore, develop, and innovate. We are able to provide our customers with the most customized solutions. Create more and better value for customers, the industry, and society. I trust that every customer who chooses us will explore the infinite possibilities of future science and technology with us.

Kindly contact us at any time by wechat or Whatsapp: +86-13915707468.