JORBIN MACHINER, we promise to supply high quality machine with high competitive prices.

Expecting cooperation with you, Let us become friendly partners, common development!

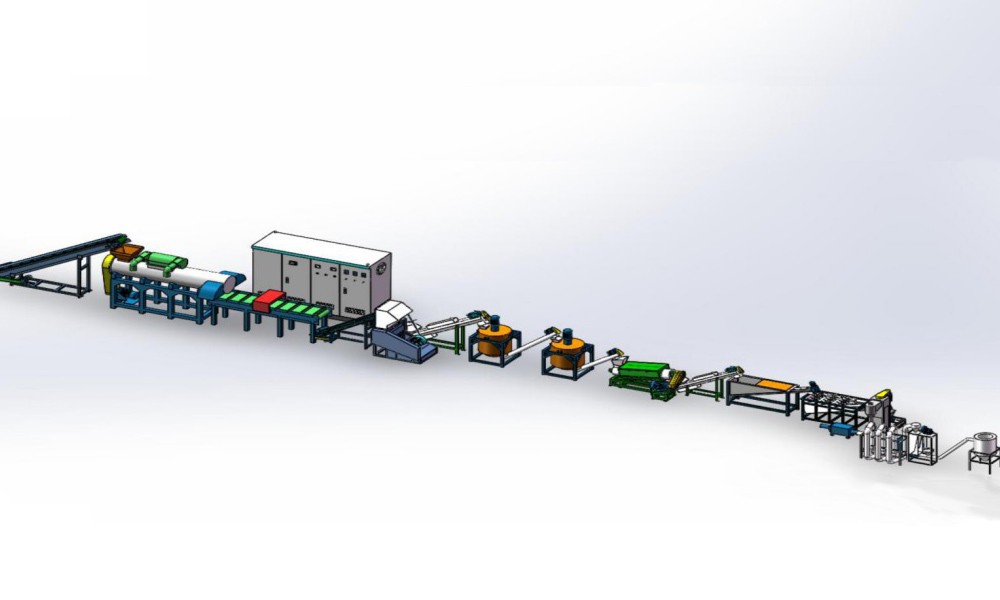

In today's era of sustainable development, the efficient recycling and reuse of waste PET plastic bottles has become particularly important. This article will delve into the workflow of the waste PET plastic bottle recycling and washing line, reveal every link in this environmental protection process, and thus present readers with a fascinating story of how waste plastic bottles are converted into renewable resources.

The first step in recycling is to collect waste PET plastic bottles from various sources. These sources include municipal recycling depots, supermarket recycling points and community recycling bins. Once used bottles are collected, they are sorted so that subsequent processing can be more efficient.

Collected waste PET plastic bottles often contain impurities, such as residual liquid, labels, or other contaminants. In the preliminary cleaning stage, professional equipment is used to remove these impurities to ensure a smoother subsequent treatment process.

After preliminary cleaning, the bottles enter the field of crusher and cracking machine. The crusher cuts waste PET plastic bottles into small particles, while the cracking machine ensures that the caps and bottoms of the plastic bottles are separated. This step provides better conditions for subsequent washing.

After being broken and cracked, the waste PET plastic bottle particles undergo multiple washing processes. This includes the use of chemical cleaners, high-temperature water, and mechanical agitation to ensure the most thorough cleaning possible. Residual labels, grease and other contaminants will be effectively removed in this step.

The cleaned waste PET plastic pellets need to be dehydrated and dried to ensure the quality of the final product. This process usually involves centrifugal dehydrators and drying equipment to completely remove moisture and prepare for the next step of processing.

After cleaning and drying, waste PET plastic particles need to be precisely sorted. Through optical sensors and airflow, plastics of different colors and textures are effectively separated, ensuring that the final product meets the standards of high-quality recycled raw materials.

Finally, the waste PET plastic particles that have been strictly processed become renewable raw materials. These pellets can be used to make new PET plastic products, enabling recycling and reducing dependence on primary resources.

The workflow of the waste PET plastic bottle recycling and washing line is a precise and coordinated environmental dance. Through collection, cleaning, separation and regeneration, we are able to convert discarded plastic bottles into valuable recycled raw materials, making an important contribution to environmental sustainability and resource recycling. The transparency of this workflow not only allows us to better understand the fate of used PET plastic bottles, but also arouses our sense of responsibility for a sustainable lifestyle.