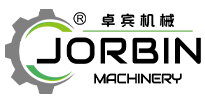

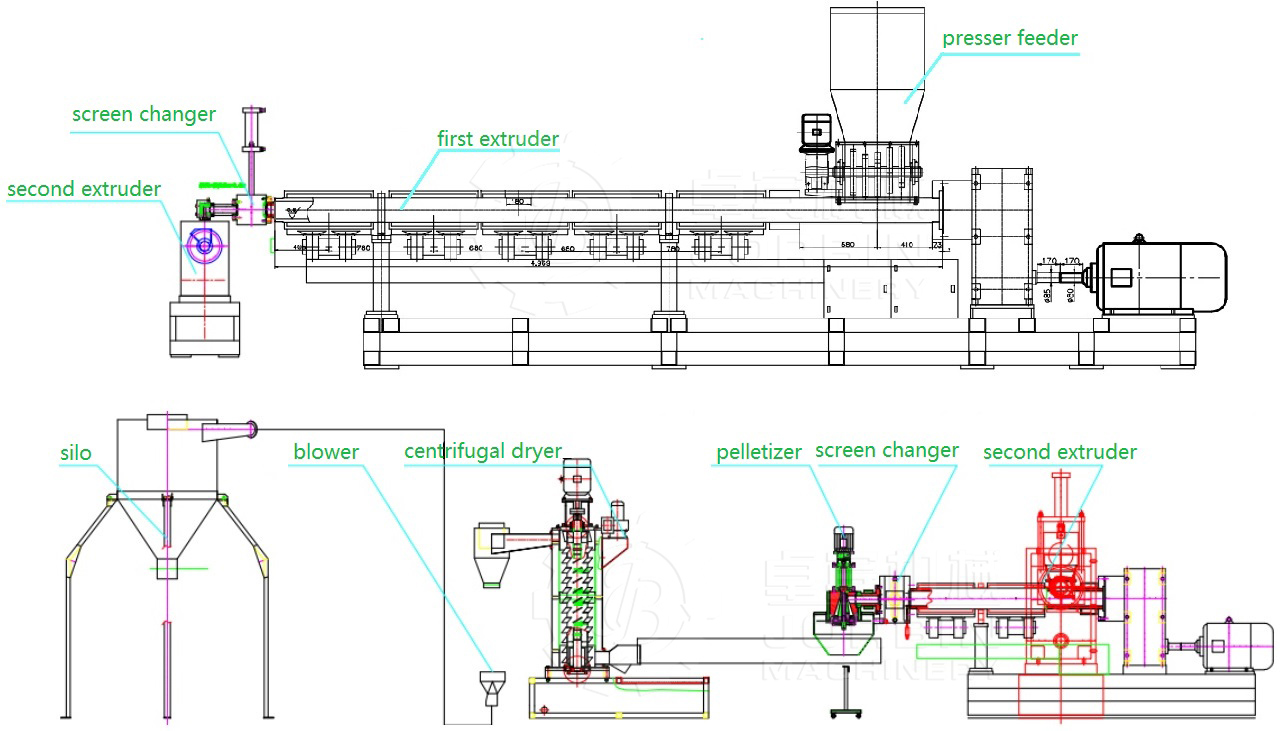

Single Screw with double cascade extruder is mainly used for processing rigid flakes, crushed flakes, regrind flakes, hollow container, buckets, Such as deskes, chairs, milk bottles, baskets and car parts together with agriculture waste film, woven bags, shopping bags.

The machine use presser feeder to feed the soft and rigid material into the extruder. So that it can save the power of the machine. The total granulation line combines quantitative feeding, high efficiency extruder,different types of filter and different types of pelletizer by modular design.