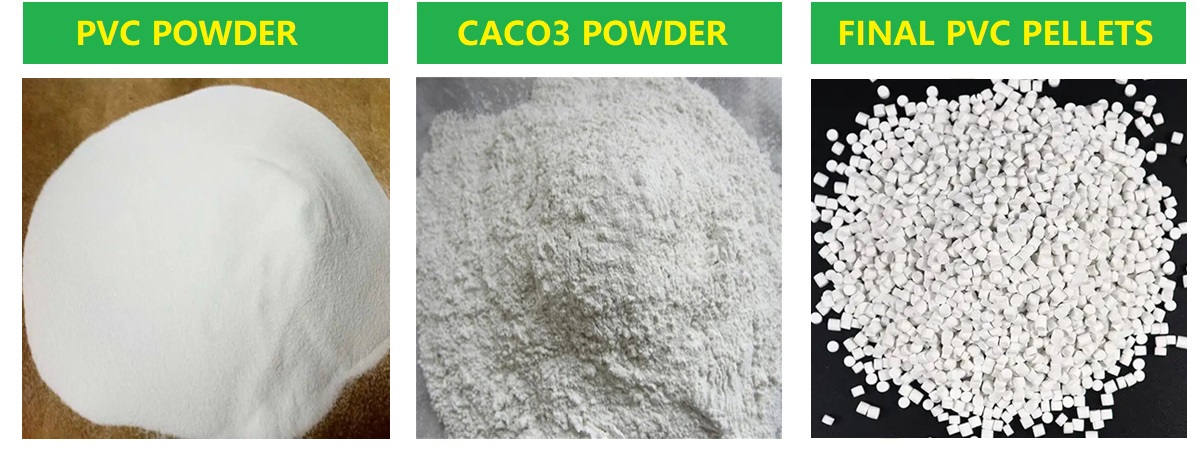

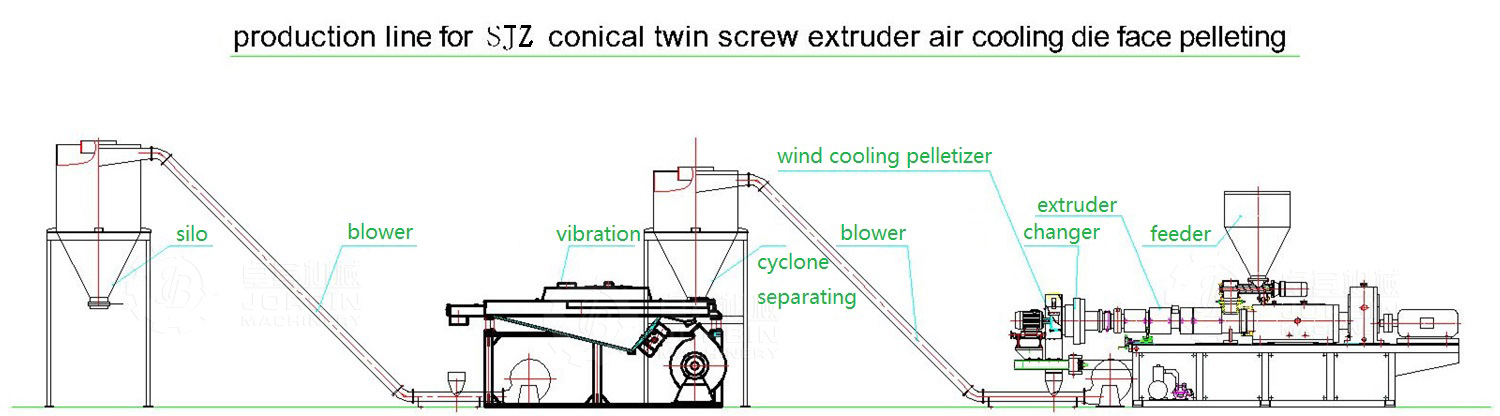

Conical twin screw extruder granulator is mainly used to compunding PVC,EVA,Caco3,fillers and other additives. The plastic granules produced are uniform, dense and beautiful. The auxiliary machine adopts die surface granulation, air feeding aggregate, vibration separation and cooling, and has the characteristics of high degree of automation and good production efficiency.

FUNCTION:

1. The multi-component quantitative feeding system ensures that the configuration of the master batch raw materials is easier and more effective. Centralized feeding system avoids dust scattering and can control each kind of material feeding quntity.

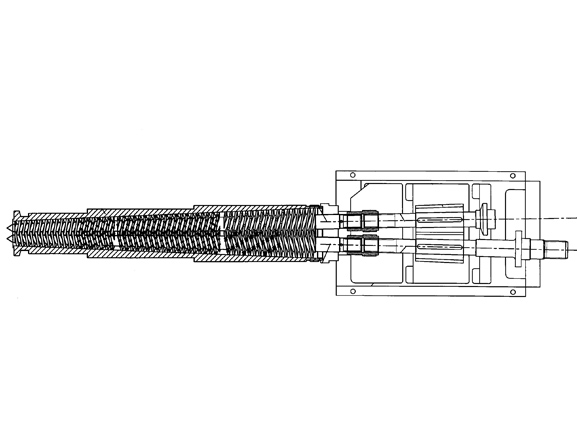

2. The material of screw and barrel is made of high-quality carbon steel andNitriding treatment, also the mold is made of high-quality carbon steel and processed by hard ironingnaturally durable. And its reasonable distribution of the outlet of the flow channel can ensure the uniform extrusion of the pellets.

3. A unique three-dimensional wind cooling die face pelletizing way can cool the pellets much more efficient.So that the final pellets can be with excellent quality.