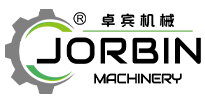

PE PP WPC wooden sawdust for processing granules extrusion granulator, which can compounding wooden sawdust and plastic(wood plastic) to make granules. The composite pelletizing extrusion machine line compounding wood powder with plastic and other additives, then it can be used to make WPC floor, door, window sheet and other WPC profiles.

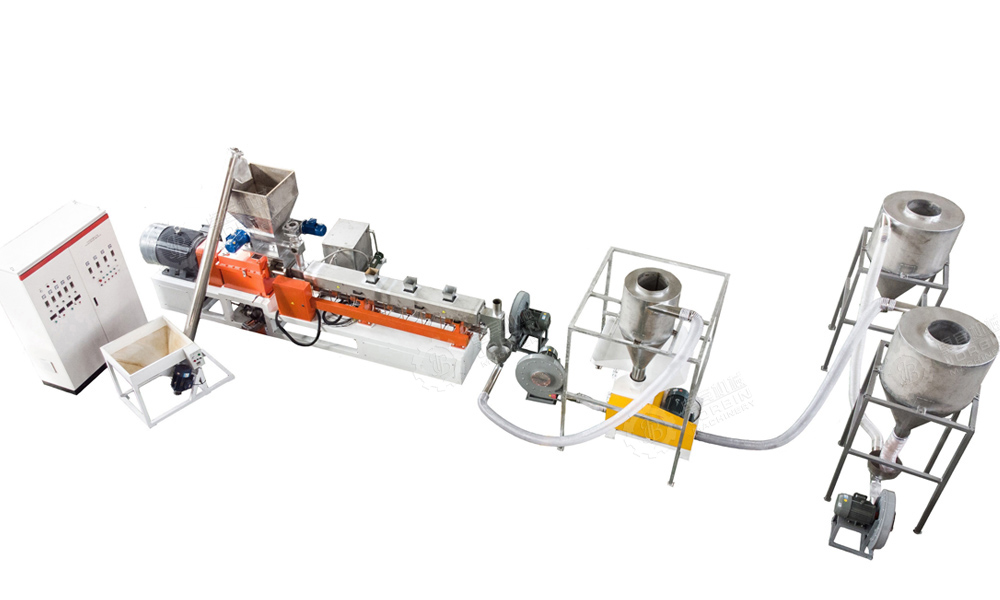

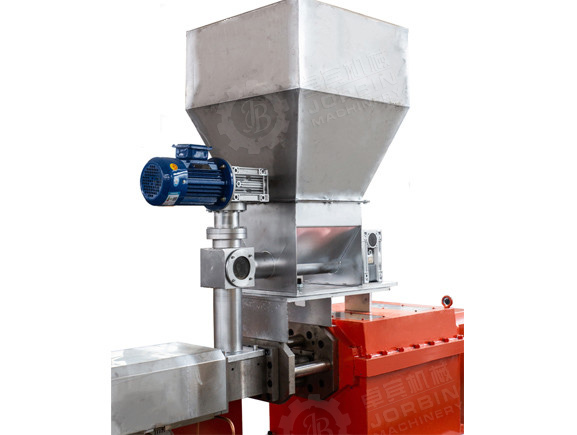

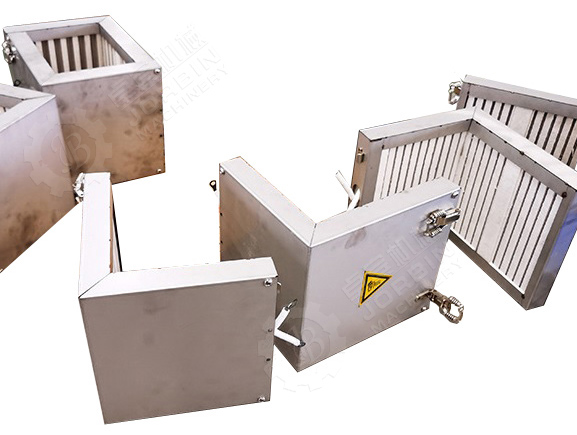

1.Twin screw and barrel with high quality alloy extrusion for pellet. each degassing with force press system, in order to press the wood go into the extruder.

2.Crusher can make the extrusion material which come out from the extruder into small granules.

3. WPC Wood plastic pelletizing machine is an efficient mixing and extrusion equipment. It consists of barrel and two intermeshing screws as the core component.It is also equipped with a feeding system , a crusher, and two transmission systems, and a control system, to form a special extrusion granulation processing equipment.The screw and barrel adopt the building block design principle, so that during processing, the length of the barrel can be changed according to the characteristics of the material, and different combinations of screw elements can be selected, in order to achieve better working conditions and effectively adapt to various process requirements. Maximize its effectiveness. Because it has good mixing, dispersion, devolatilization and self-cleaning functions, it can avoid the material wrapping the shaft and forming walls during the extrusion process. At the same time, the material surface is constantly updated as the screw rotates, which is more conducive to Treatment of volatile matter removal/removal agent, high-speed dissolution.