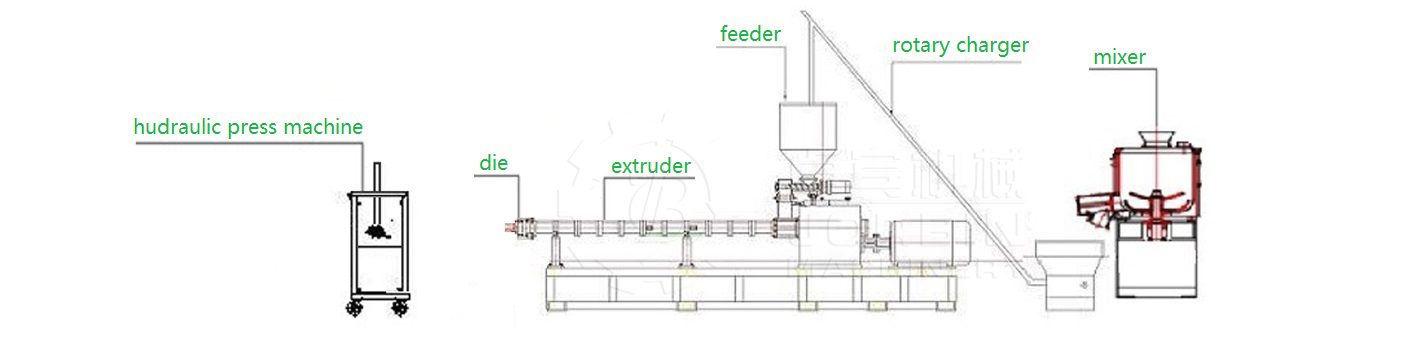

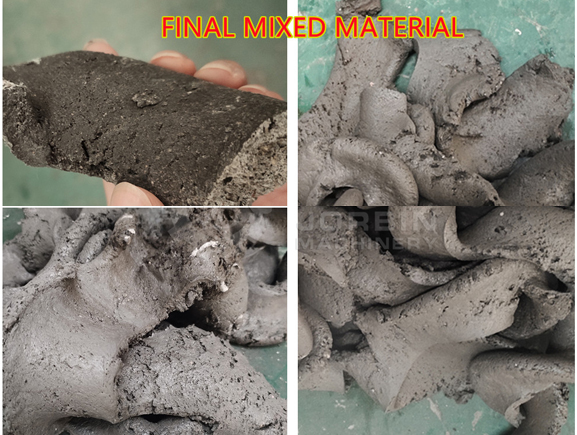

Mix sand with PVC and PP crushing extrusion to make block,Extruison and mixing unit from the machine to make block or bricks and to pave roads.

Material is mixed by mixer and come into the rotary charger, Then rotary charger will send the material into the extruder, After the extrusion, the material will mixed together equaly.

Many kinds of plastic materials can be processed directly without degassing.After extrusion the material can be used to make block.

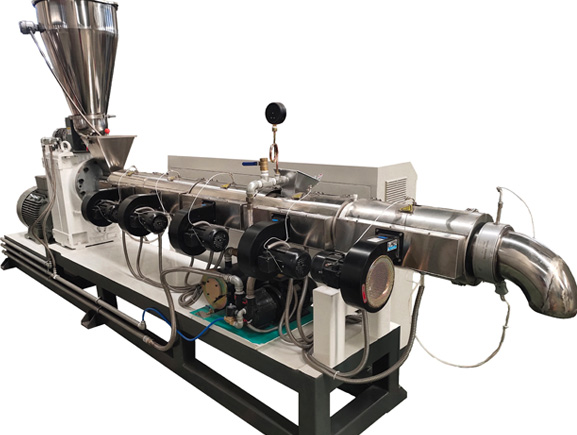

Heating screw extruder for plastic sand composition from waste plastic HDPE LDPE PP PVC and sand

How the machine works:

1. First you can weigth each material, like we use pp mixture PE - 25 kg,filler - 25 kg, pvc dust powder PVC -15 kg,Sand - 45 kg, And you can use up to your requirement, PP ,PE PVC all are possible. .

2. Each material put into the mixer and the mixer will mix all of these material for about 10mins, and then open the mouth on the mixer, the material will come down into the Rotary charger hopper.

3. Rotary charger send the mixed material into the extruder feeder, When the feeder is full, the Rotary charger will stop by itself. If there is no material in the hopper, you can restart the rotary charger.

4. Then material is plasticised and degassed in the extruder screw, next the material will be plasticised and melt together in the screw, with the extrusion, the material come out.

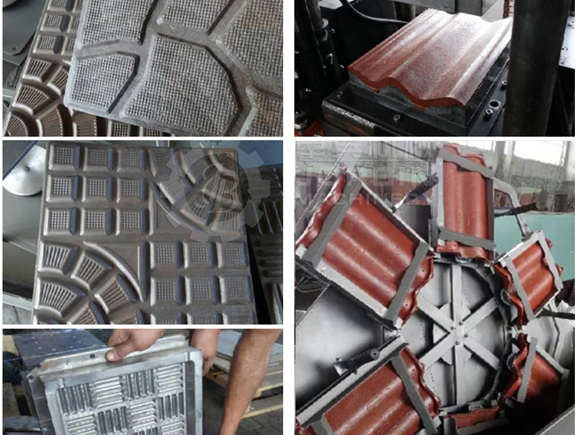

5. After weigth the block material, then hydraulic pressre can make each kinds of blocks with its design.