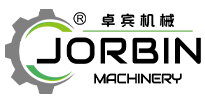

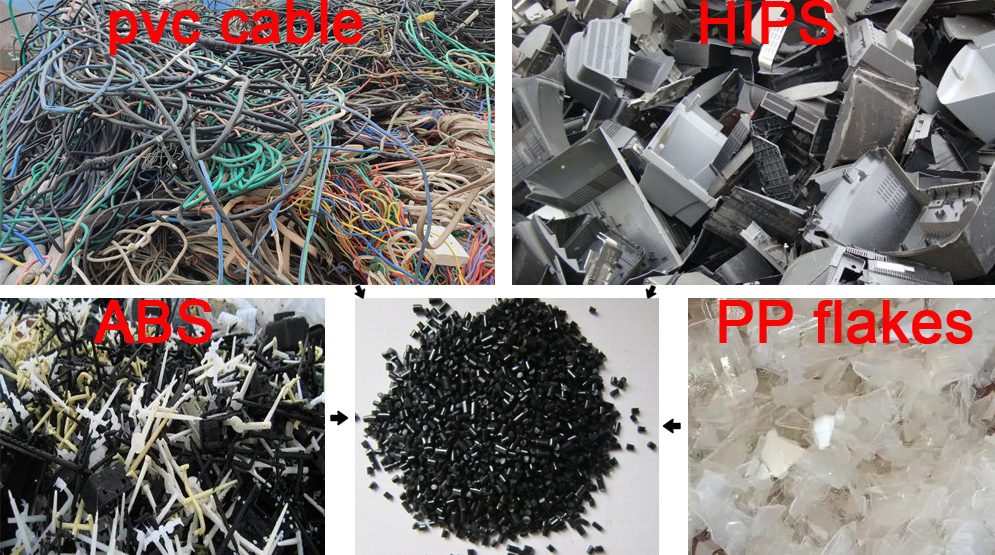

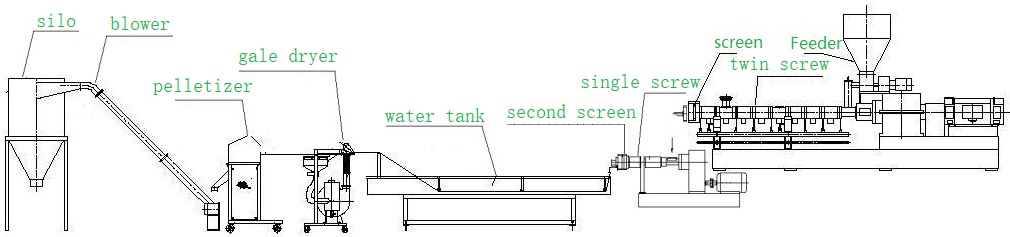

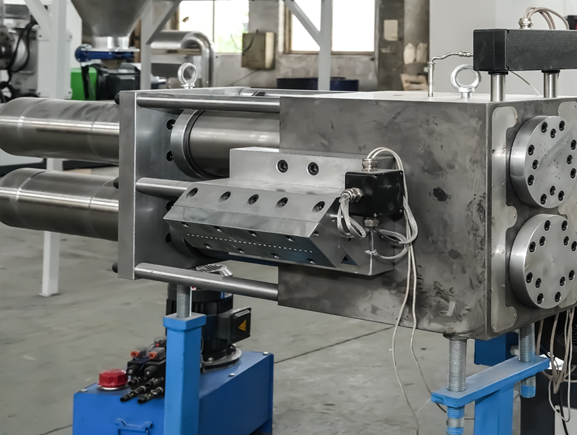

Two stage extrusion granulator with first twin screw extrusion and second single Screw extrusion.It is mainly used for processing PVC,PP,ABS,PS and so on.

The first twin screw extruder is mianly used to compound all kinds of material. With the meshing blocks of twin screw, all kinds of material can be compounded well. And the second single extruder is mainly use to push the material out, with the die to cut them into pellets.

Of course, we have single stage extruder, double stage extruder for choosing. According to different material and different requirements, each machine can be specilized desigined.