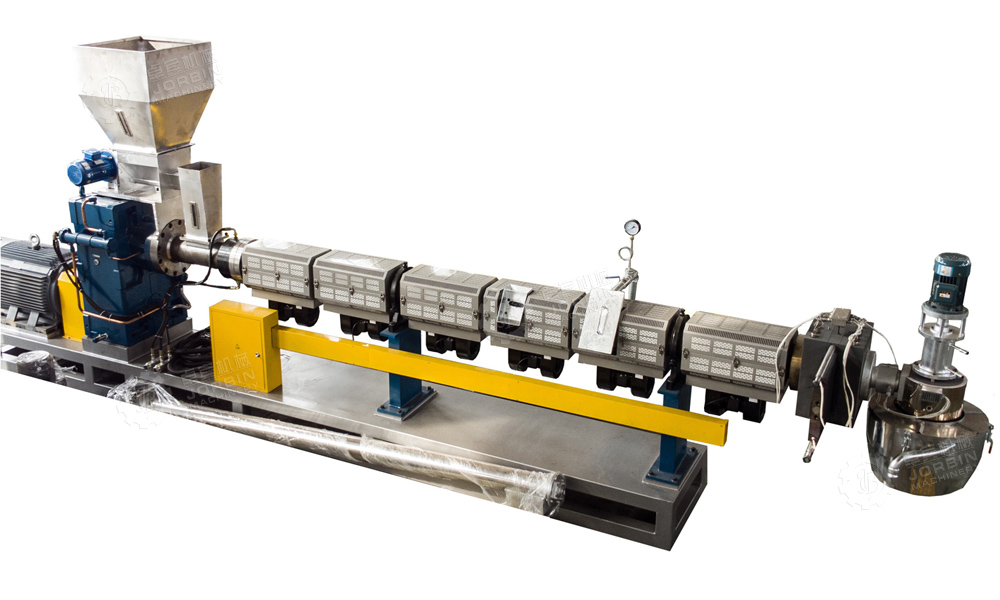

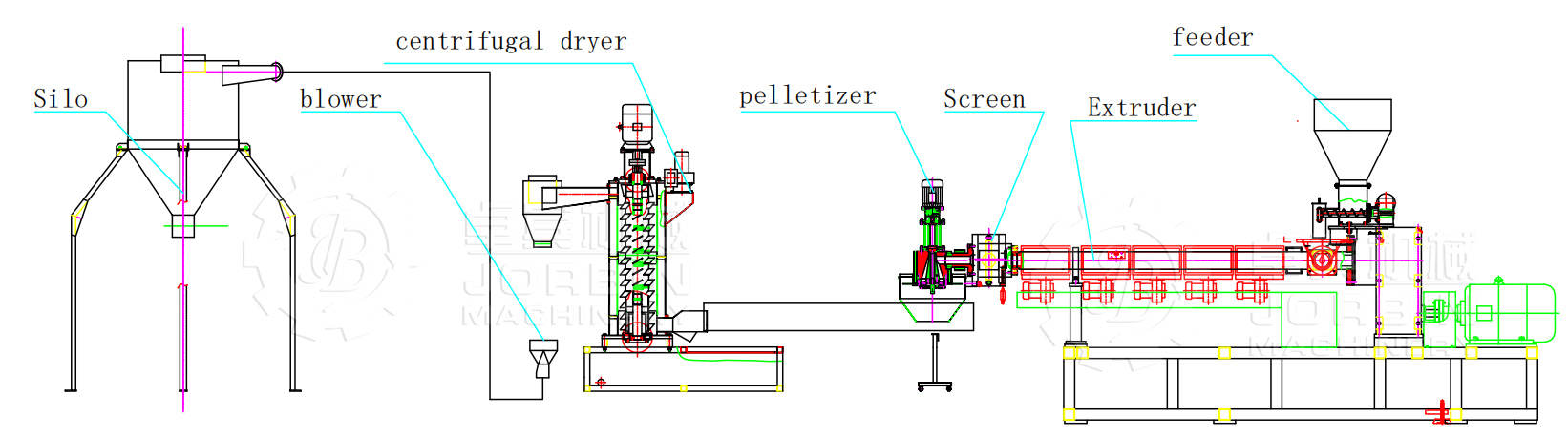

Single Screw cascade extruder with water-ring pelletizer system is mainly used for processing rigid flakes, crushed flakes, regrind flakes, hollow container, buckets, Such as deskes, chairs, milk bottles, baskets car battery boxes and car parts.

After crushed,washed and dried, then the plastic flakes need to be granuated by extruders. Finally hese granules can be further processed into various plastics products by blowing, injection and calendering. The total granulation line combines quantitative feeding, high efficiency extruder,different types of filter and different types of pelletizer by modular design.